The machine operates based on the All-In-All-Out principle:

1) The entire pit is filled with raw materials.

2) The machine starts agitating the materials moving them in both directions.

3) After a period ranging from several days to several weeks, the dried and processed product can be removed from the pit all at once.

It is important to note that the processing duration may vary depending on the weather and season.

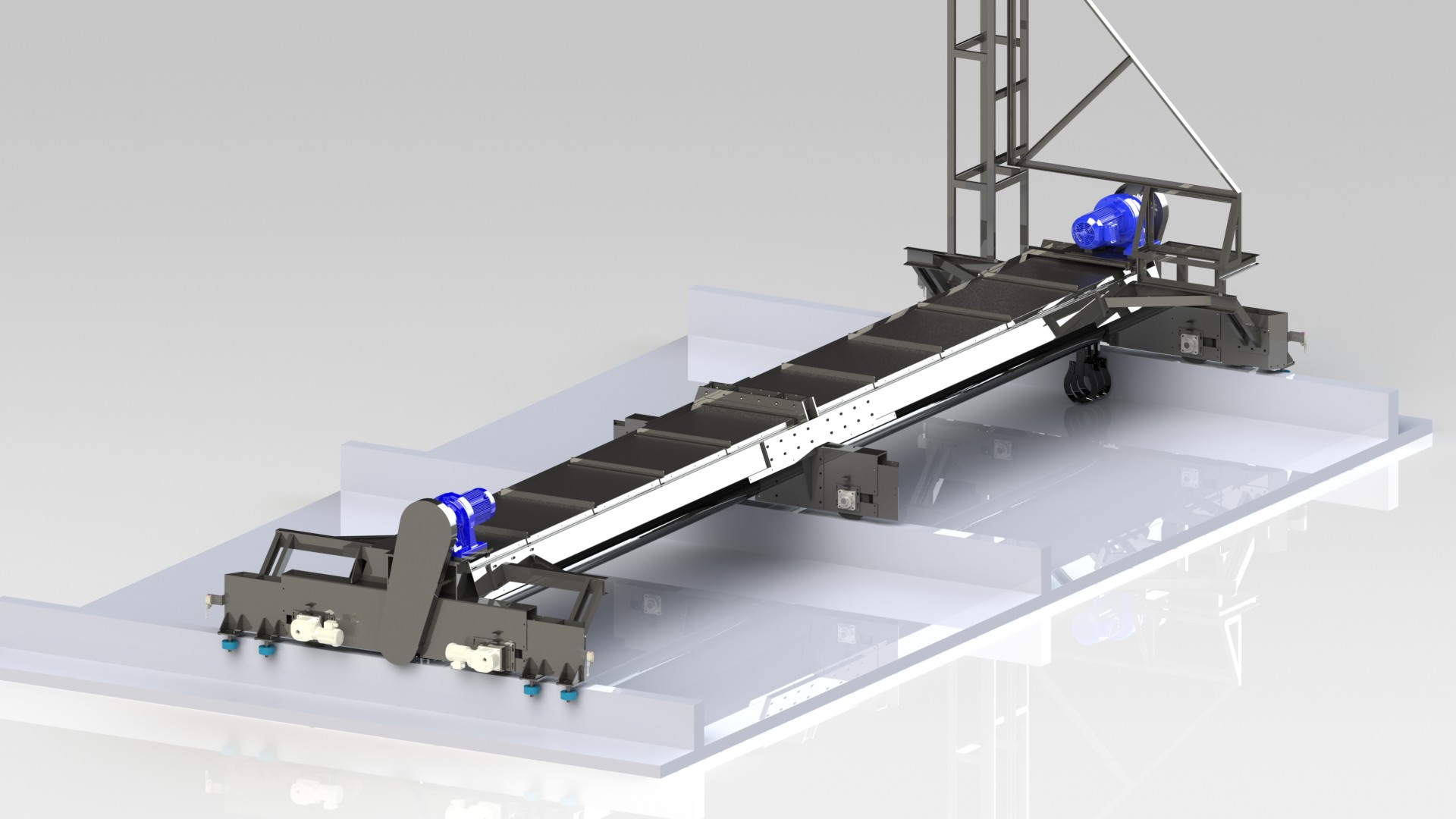

The KSNF model is an innovation of KSN designed as a dryer & semi-composter.

Its unique advantage lies in its single rail design, with the other side`s wheels running above the floor. This allows the materials to be placed anywhere along the side and easily removed once they have been dried.

The KSN machine, along with our other machines, utilizes our uniquely designed hatchet blades, which efficiently cut the materials.

The final product is finely chopped and safe to use.

| Model | Capacity (m3/day) | Pit Width (m) | Manure Height (mm) | Rail Height (mm) | Rotary Motor (kW) | Running Motor (kW) | Running Speed (m/min) |

|---|---|---|---|---|---|---|---|

| KSN-4000R (KSN-4000WR) | Max.180 (360) | 4x1 (4x2 pits) | 300 | 350 | 7.5 (7.5x2) | 0.2x2 (0.1x4) | 0.6-1.7 |

| KSN-5000R (KSN-5000WR) | Max.225 (450) | 5x1 (5x2 pits) | 300 | 350 | 7.5 (7.5x2) | 0.2x2 (0.1x4) | 0.6-1.7 |

| KSN-6000R (KSN-6000WR) | Max.270 (540) | 6x1 (6x2 pits) | 300 | 350 | 11 (11x2) | 0.2x2 (0.1x4) | 0.6-1.7 |

| KSNF-6000R | Max.270 | 6 | 300 | 350 | 11 | 0.4x2 | 0.75-2.25 |