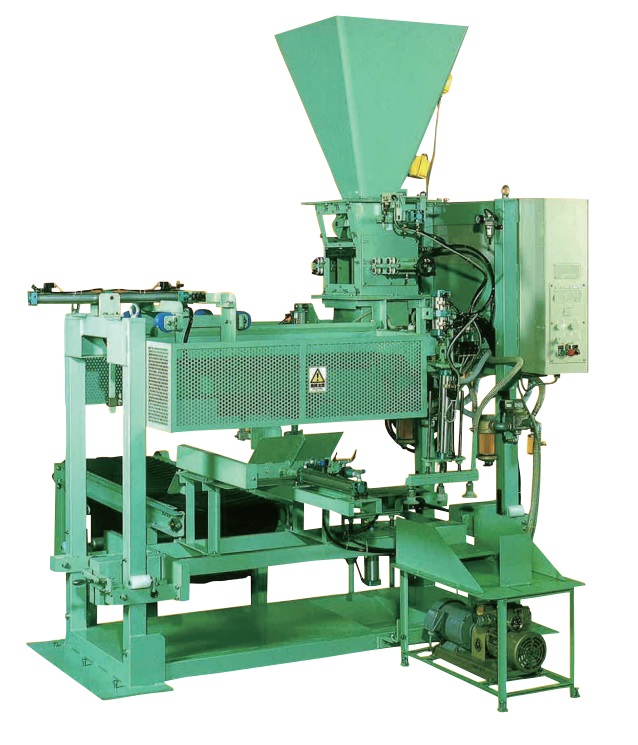

The machine is designed for bagging various granular or powder products into polyethylene bags. Users can choose between volume weighing and gravity weighing options for precise measurements. Depending on the type of product (granular or powder), appropriate feeder systems such as screw feeders, cut-off gates, or belt feeders can be selected to optimize the machine's performance across different applications.

This machine features an automatic system for bag feeding, filling, and sealing with an impulse sealer. Its compact design requires minimal space, enhancing packing efficiency and reducing labor costs. It includes a pre-installed impulse sealer, eliminating the need for an additional heat sealer downstream.

It is a bagging machine that uses non-woven fabric bags for packaging. It can pack weights of upto approximately 50kg. By using a belt conveyor and combining it with an automatic sewing machine, it enables efficient bagging, significantly reducing the workload of the bagging process.

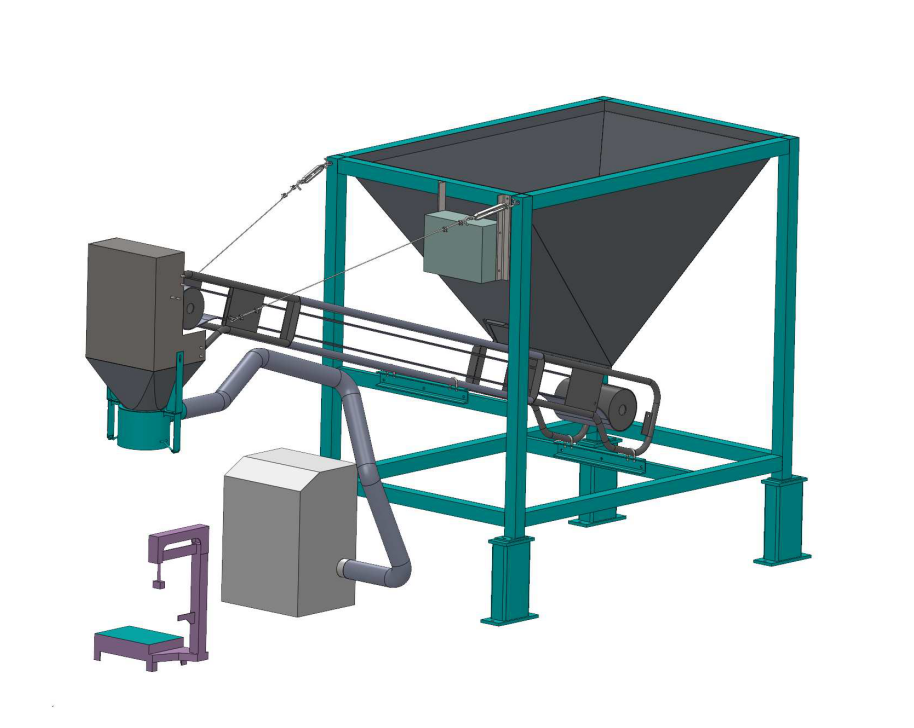

This system is designed to boost productivity while keeping costs and labor to a minimum. It is cost-effective, offering a reliable solution without the high cost of automation. Built with durable components, it requires minimal maintenance, ensuring efficient, continuous operation with little downtime.

The production of this machine is approximately 90 bags per hour, with each bag weighing 50 kg. It offers flexible weighing capacities of 20 kg, 50 kg, and 100 kg.

The palletizer can be combined with semi-automatic or fully automatic packers to streamline the product bagging process.

Full-Auto packer

Full-Auto packer

Semi-Auto Packer

Semi-Auto Packer

Palletizer

Palletizer

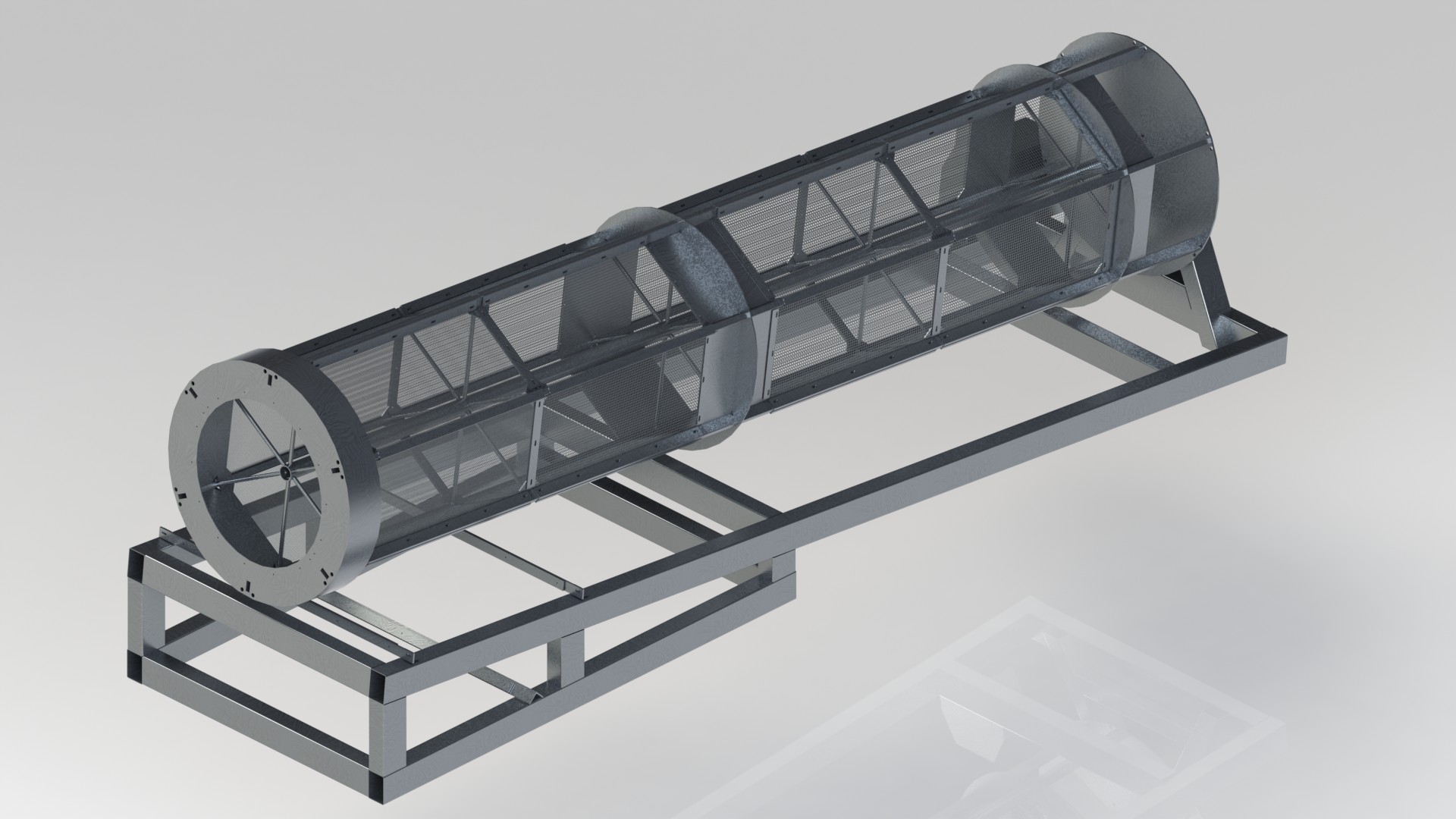

Trommel

A trommel is a machine used to screen the final product discharged from the composter, sorting the fertilizer by size through a rotating sieve.

Trommel

A trommel is a machine used to screen the final product discharged from the composter, sorting the fertilizer by size through a rotating sieve.

Packers and Palletizers

Maximize your efficiency and streamline your operations with this state-of-the-art packaging and palletizing equipment. Designed to handle a variety of products, this equipment offers versatility, precision, and reliability for your packaging needs.

Packers and Palletizers

Maximize your efficiency and streamline your operations with this state-of-the-art packaging and palletizing equipment. Designed to handle a variety of products, this equipment offers versatility, precision, and reliability for your packaging needs.