With Venus 2.0 you can clean multiple levels of cages, up to a height of 4 meters (6 tiers), and accommodate aisle widths ranging from 0.6 meters to 1.4 meters.

Customers can easily operate and configure the machine using their own tablets. They can save cleaning patterns, allowing them to repeat the cleaning process in multiple poultry houses with just one setup.

The flexible programming allows the nozzles to rotate while the mechanism moves up and down, enabling the cleaning of hard-to-reach spots.

By increasing the diameter of the wheels, the traction rate is improved, allowing continuous cleaning of cages up to 100 meters in length.

The hose reel is synchronized with the machine body, and the hose is automatically unwound and rewound. Also, with just one button, the hose reel follows the machine body and moves along the aisle.

It uses a crank mechanism for increased durability. The pump can reach a pressure of 25MPa. It requires minimal maintenance and can also be used separately for manual cleaning.

| Model | Tiers | Washing Range (mm) | Water Consumption (L/min) | Water Pressure (MPa) | Voltage | Weight (kg) |

|---|---|---|---|---|---|---|

| Venus 2.0 | Up to 6 tiers | 800 From the top of the nozzle | 15 (one side) 30 (both sides) | 15-25 | Single phase (100V 0.98kW) | 220 (main unit) 190 (hose reel) |

Before

Before

After

After

High pressure of 25 MPa

High pressure of 25 MPa

Cage Cleaning Robot

Cage Cleaning Robot  Slat Cleaner

Highly efficient and effortless solution for cleaning slats with and without legs. This innovative device not only saves you time, but also enhances the overall hygiene level of your poultry house.

Slat Cleaner

Highly efficient and effortless solution for cleaning slats with and without legs. This innovative device not only saves you time, but also enhances the overall hygiene level of your poultry house.

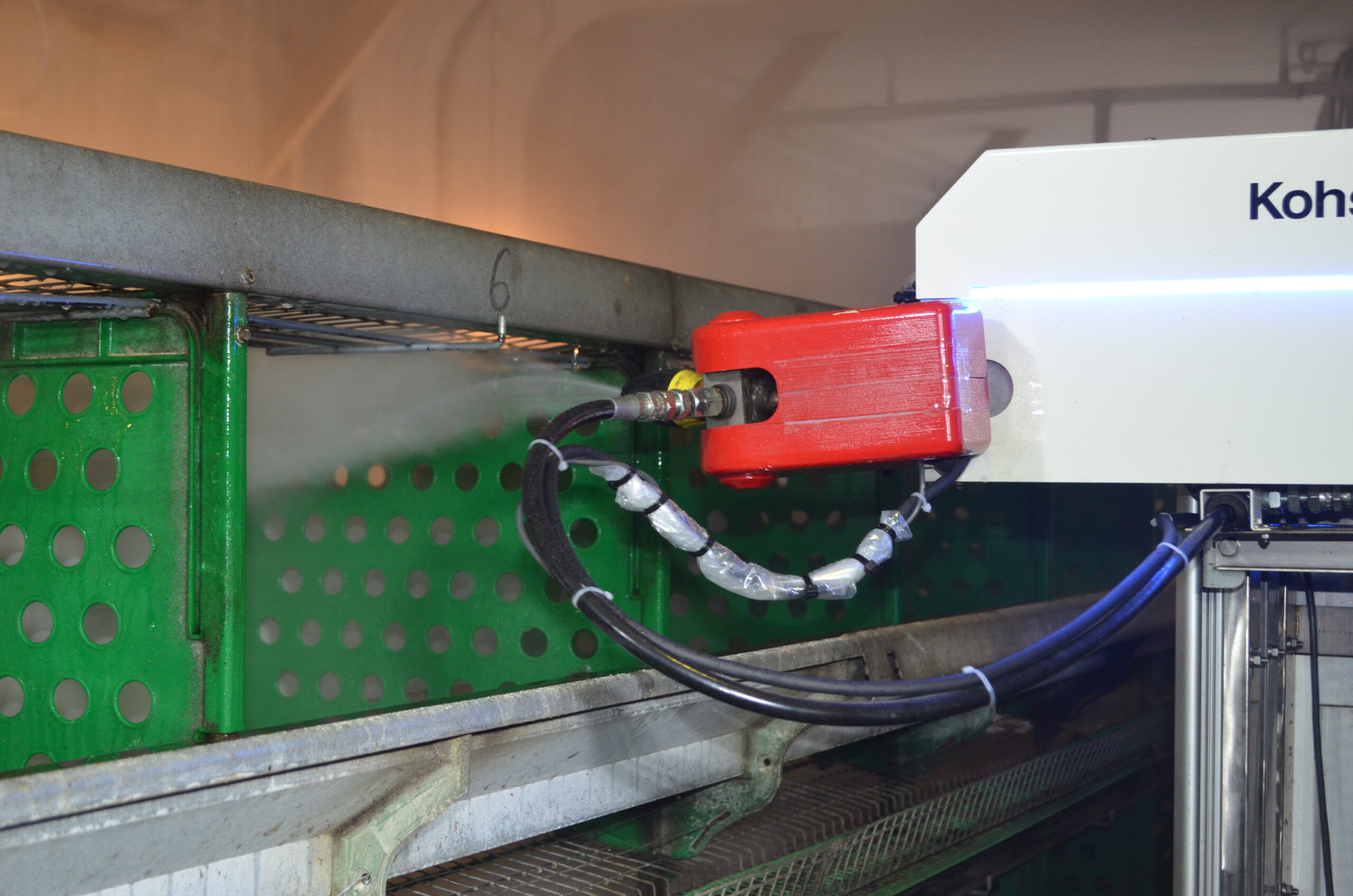

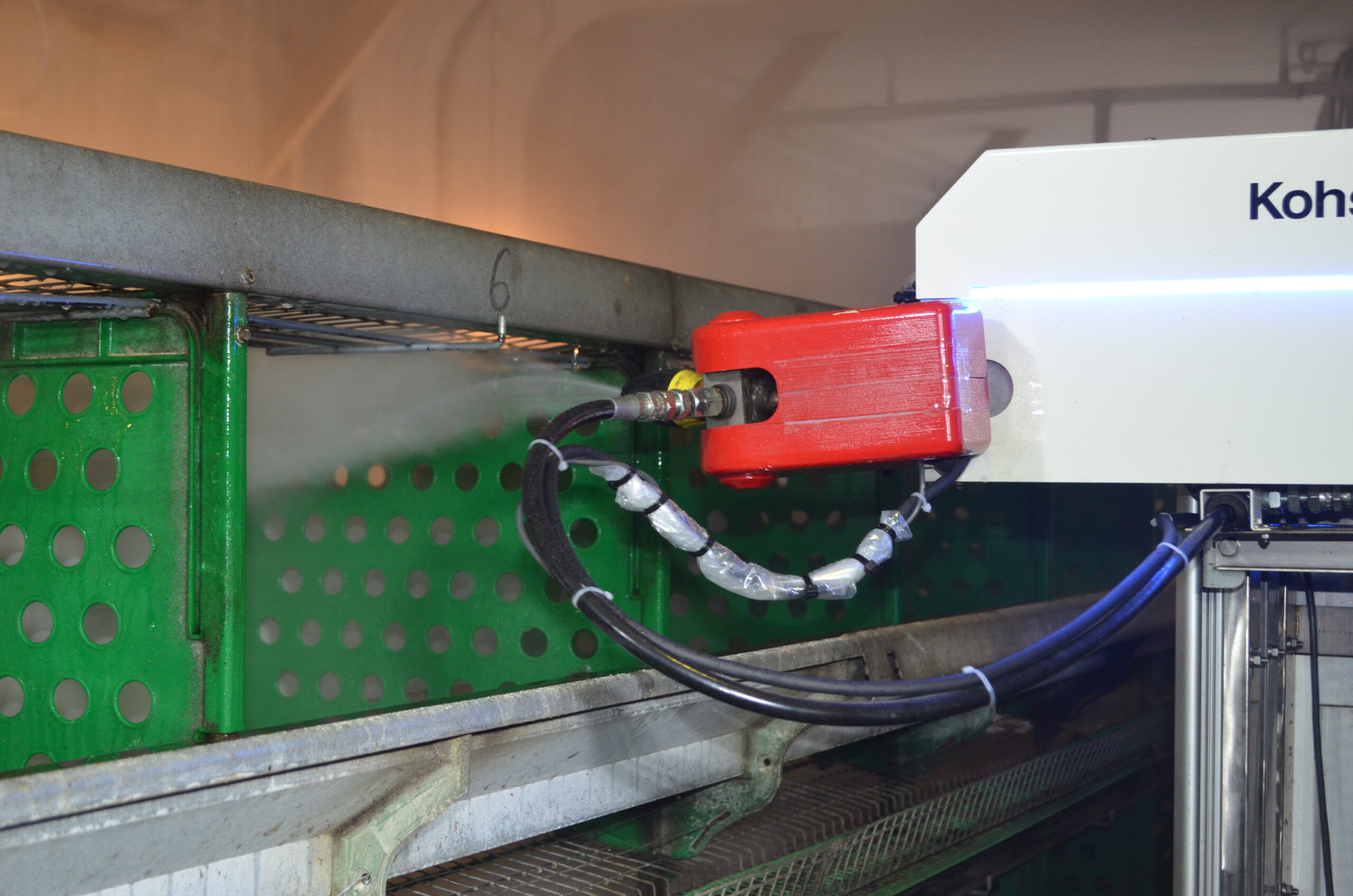

Rack Cleaner

Introducing our innovative Rack Cleaner, specifically designed for washing bird transportation racks. With a high-pressure capability of 25 MPa, this device effortlessly removes dirt and grime, even from hard-to-reach spots.

Rack Cleaner

Introducing our innovative Rack Cleaner, specifically designed for washing bird transportation racks. With a high-pressure capability of 25 MPa, this device effortlessly removes dirt and grime, even from hard-to-reach spots.