The machine operates based on the All-In-All-Out principle:

1) The entire pit is filled with raw materials.

2) The machine starts drying the materials moving them in both directions.

3) After a period ranging from several days to several weeks, the dried and processed product is extracted from the pit all at once.

It is important to note that the processing duration may vary depending on the weather and season.

This machine can also be utilized for drying various types of produce, including vegetables, grains, and even coffee beans. Its blades operate smoothly and gently, ensuring the integrity of the materials throughout the drying process.

This dryer employs T-shaped blades.

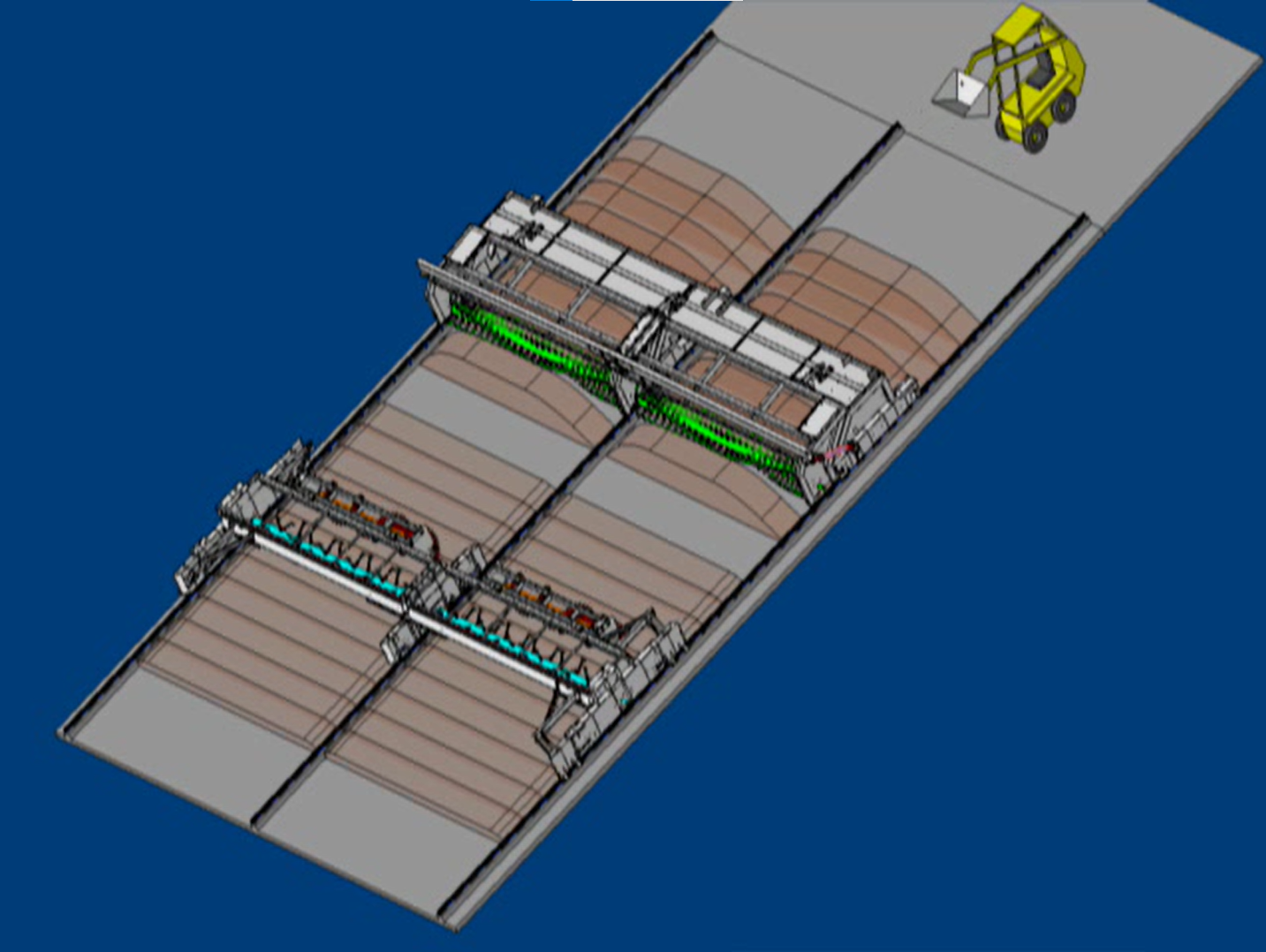

It is possible to join the two machines (KN and KS-H) together and use KS-H to finish drying the final product that comes of the KN Composter by transferring the product directly to the KS-H Dryer. This efficient process allows for a continuous transition from the composter to the dryer, ensuring that the final product is dried to perfection.

| Model | Capacity (m3/day) | Pit Width (m) | Material Height (mm) | Rail Height (mm) | Rotary Motor (kW) | Running Motor (kW) | Running Speed (m/min) |

|---|---|---|---|---|---|---|---|

| KS-4000H (KS-4000HW) | Max. 3 (6) | 4x1 (4x2 pits) | 300 | 300 | 3.7 (3.7x2) | 0.4x2 | 2.1 |

| KS-5000H (KS-5000HW) | Max. 3.75 (7.5) | 5x1 (5x2 pits) | 300 | 300 | 5.5 (5.5x2) | 0.4x2 | 2.1 |

| KS-6000H (KS-6000HW) | Max. 4.5 (9) | 6x1 (6x2 pits) | 300 | 300 | 5.5 (5.5x2) | 0.4x2 | 2.1 |