Our composters are built for industrial-scale composting. Whether processing manure or handling large amounts of organic waste, our machines offer the capacity and efficiency needed to manage significant volumes from 4.4 to 70t/day, making them ideal for large farms and industrial composting facilities.

The main principle of our technology is aerobic composting. The goal is to promote oxygen circulation to activate aerobic bacteria, increase the temperature, accelerate the decomposition of organic materials and minimize bas odors. This method produces premium-quality compost, rich in nutrients and beneficial for soil health.

Our composters are engineered with corrosion-resistant materials to withstand harsh environments and continuous use. Designed for longevity, Kohshin machines offer perfect durability, ensuring reliable performance over the years.

What sets our composters apart is the incorporation of specially designed hatched blades. These hatchet-type blades revolutionize the composting process. They allow for the gathering of manure in a mountain-like shape, effectively increasing the surface area and facilitating better air circulation throughout the compost.

Since our composters are equipped with uniquely designed hatchet blades, they ensure uniform chopping of the materials. In the case of layer chicken manure, the final product is even more pelletized. As a result, our final product is guaranteed to be consistently uniform.

| Model | Capacity (m3/day) | Pit Width (m) | Manure Height (mm) | Rotary Motor (kW) | Running Motor (kW) | Sliding Motor (kW) | Hydraulic Motor (kW) | Running Speed (m/min) |

|---|---|---|---|---|---|---|---|---|

| KNLL-4000(KNLL-4000W) | 5.9-11.8(11.8-23.6) | 4m(x2 pits) | 900 | 7.5x2 | 0.1x4 | (0.1x2) | 1.5 | 0.6-1.7 |

| KNLL-5000(KNLL-5000W) | 7.7-15.4(15.4-30.8) | 5m(x2 pits) | 900 | 7.5x2 | 0.1x4 (0.2x4) | (0.1x2) | 1.5 | 0.6-1.7 |

| KNLL-6000(KNLL-6000W) | 9.5-19.0(19.0-38.0) | 6m(x2 pits) | 900 | 7.5x2 | 0.2x4 | (0.1x2) | 1.5 | 0.6-1.7 |

| KNLL-4000H(KNLL-4000HW) | 9.0-18.0(18.0-36.0) | 4m(x2 pits) | 1200 | 7.5x2 | 0.1x4 | (0.1x2) | 1.5 | 0.6-1.7 |

| KNLL-5000H(KNLL-5000HW) | 11.7-23.4(23.4-46.8) | 5m(x2 pits) | 1200 | 11x2 | 0.1x4 (0.2x4) | (0.1x2) | 1.5 | 0.6-1.7 |

| KNLL-6000H(KNLL-6000HW) | 14.5-29.0(29.0-58.0) | 6m(x2 pits) | 1200 | 11x2 | 0.2x4 | (0.1x2) | 1.5 | 0.6-1.7 |

| KNLL-4000SH(KNLL-4000SHW) | 14.6-29.2(29.2-58.5) | 4m(x2 pits) | 1500 | 15x2 | 0.4x4 | (0.2x2) | 2.2 | 0.6-1.7 |

| KNLL-5000SH(KNLL-5000SHW) | 19.1-38.2(38.2-76.5) | 5m(x2 pits) | 1500 | 18.5x2 | 0.4x4 | (0.2x2) | 2.2 | 0.6-1.7 |

| KNLL-6000SH(KNLL-6000SHW) | 23.6-47.2(47.2-94.5) | 6m(x2 pits) | 1500 | 18.5x2 | 0.4x4 | (0.2x2) | 2.2 | 0.6-1.7 |

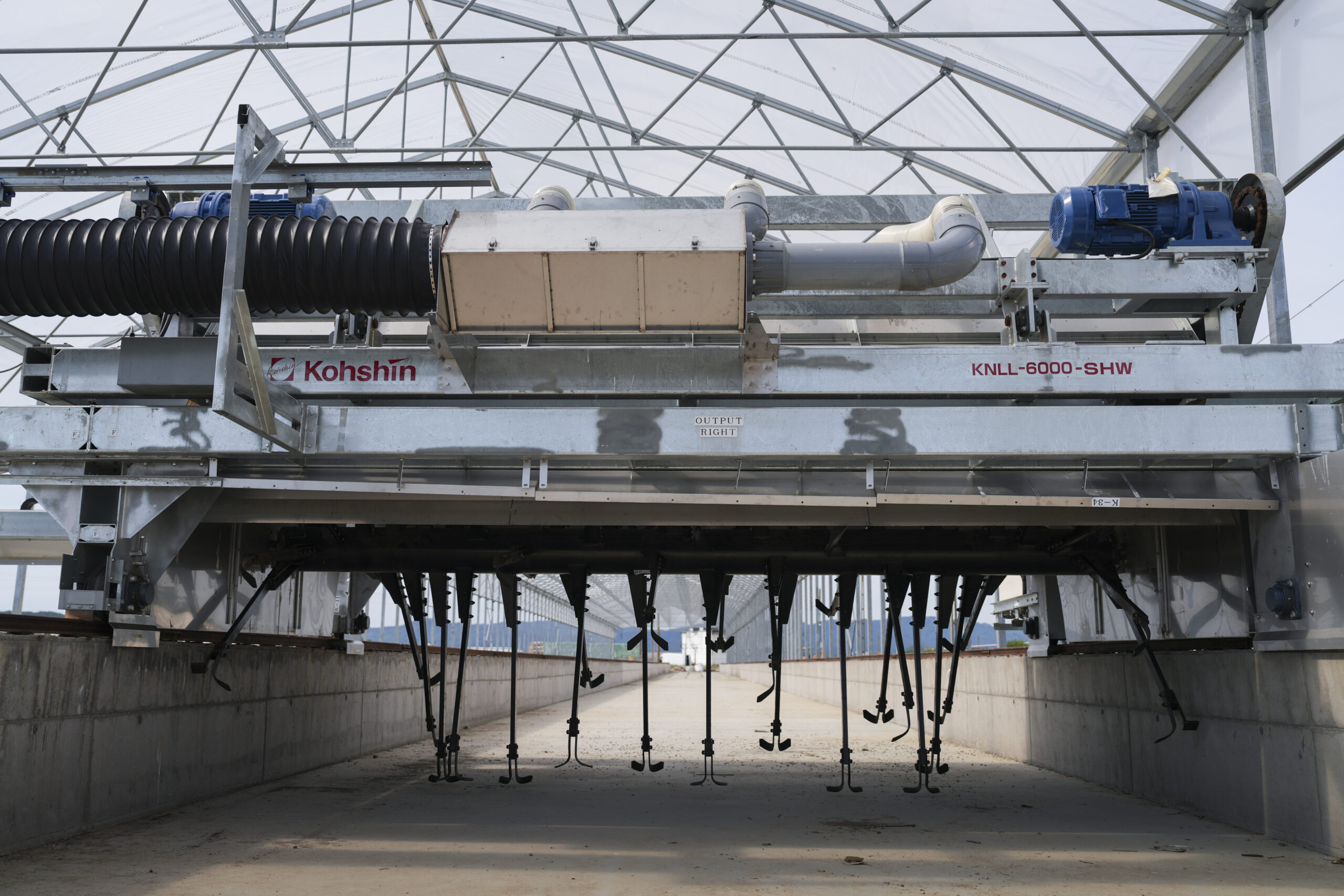

KNLL Composter

Our composting technologies use aerobic composting principles to speed up the process, kill pathogens and weed seeds, reduce odors and greenhouse gas emissions, and create

KNLL Composter

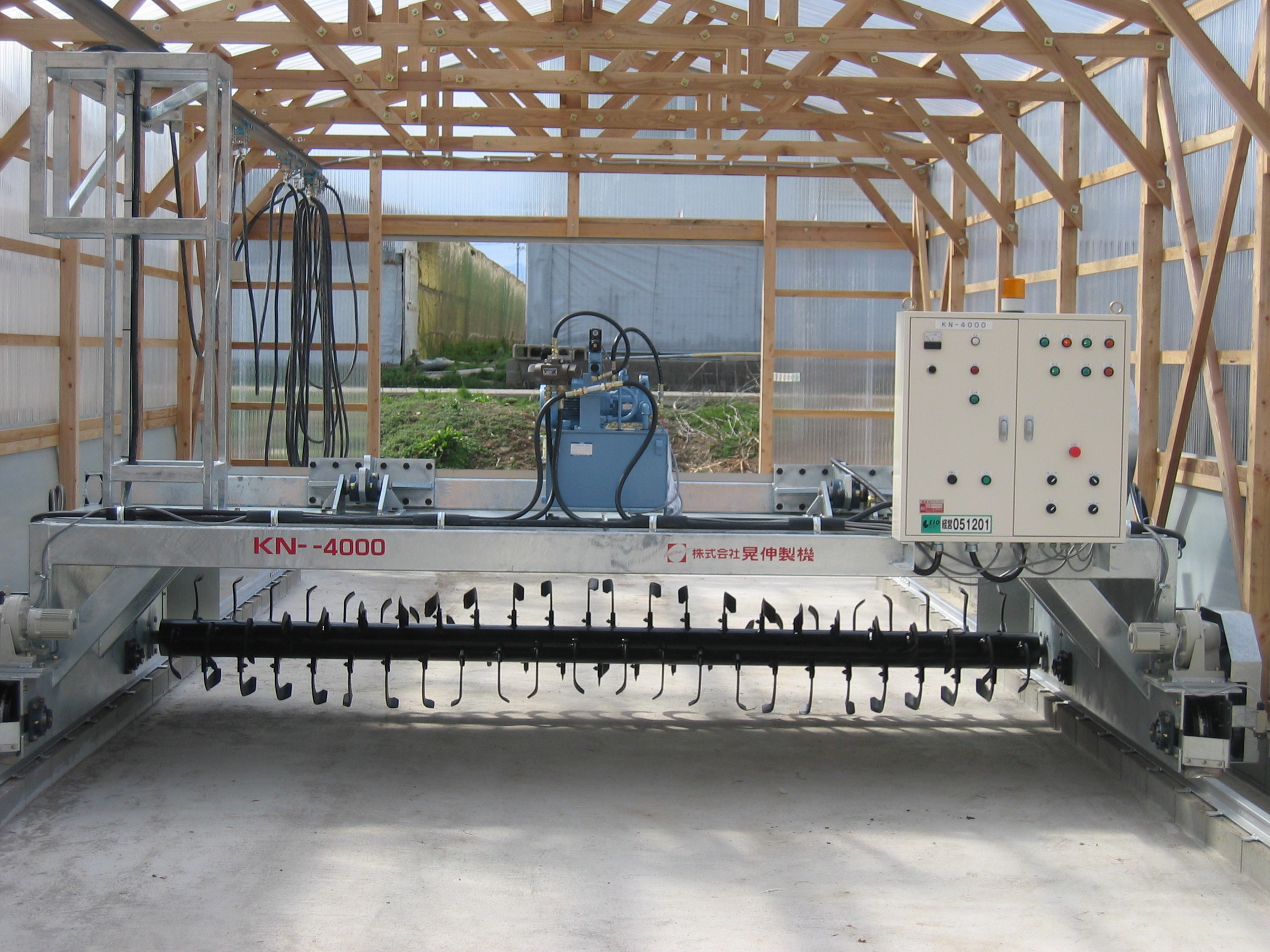

Our composting technologies use aerobic composting principles to speed up the process, kill pathogens and weed seeds, reduce odors and greenhouse gas emissions, and create  KN Composter

Investing in the KN Type Fermenter ensures quality and efficiency for small to medium-scale processing facilities.

KN Composter

Investing in the KN Type Fermenter ensures quality and efficiency for small to medium-scale processing facilities.

Soilath® System: Online Monitoring

Soilath® System has been specifically designed to monitor the conditions within waste piles. This system helps to achieve optimal aerobic conditions by adjusting the blower timer settings and analyzing data received from the sensors.

Soilath® System: Online Monitoring

Soilath® System has been specifically designed to monitor the conditions within waste piles. This system helps to achieve optimal aerobic conditions by adjusting the blower timer settings and analyzing data received from the sensors.